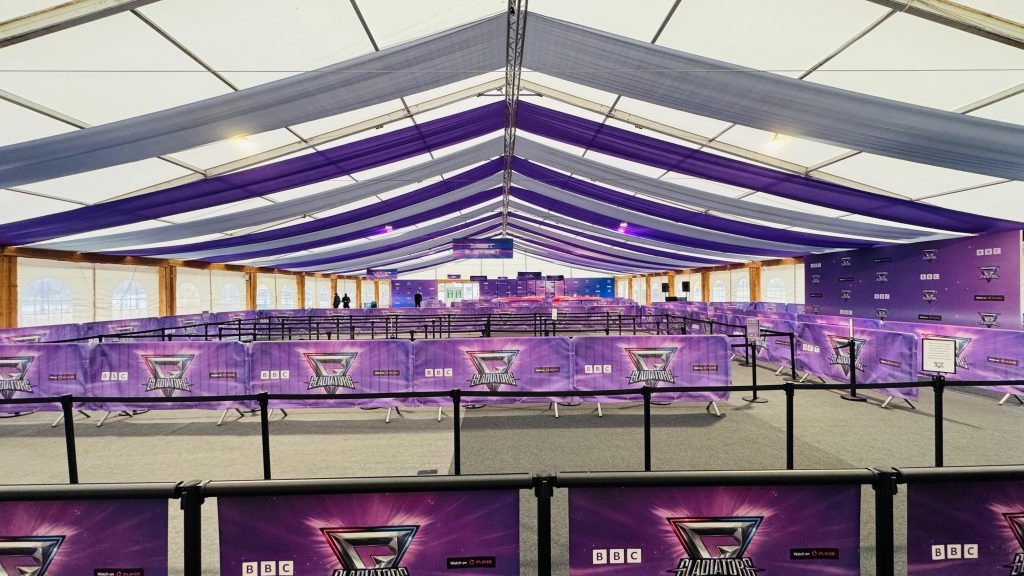

Transform your indoor and outdoor spaces sustainably with our eco-friendly print, signage, digitisation, and Installation solutions. We combine innovative design, high-quality materials, and green practices to deliver impactful, environmentally responsible results for your business.

Request a Quote

Thank you

Thank you! Someone will reach out to you shortly.

Products

Services

Industries

Resources

© 2025 ARC-UK Technologies, Inc. (ISO/IEC 27001:2022 Certified and SOC2 Compliant)

ARC Manchester

ARC Suffolk

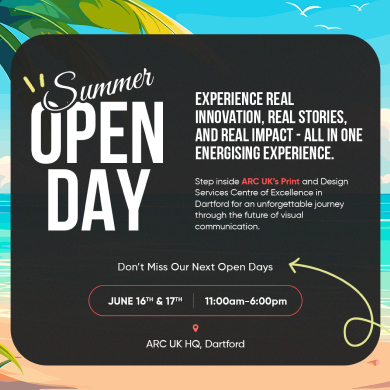

DARTFORD, Unit 5, Dartford Trading Estate, Victoria Road, Dartford, DA1 5XS, United Kingdom

ARC Birmingham

LONDON, Unit GG.014, 30 Great Guildford St London SE1 0HS , United Kingdom

BRIDGWATER, Unit 5 Woodlands Court Business Park, Bristol Road Bridgwater, TA6 4FJ , United Kingdom

ARC LEEDS

SCOTLAND, Wrae Farmhouse Broughton, Biggar, Scottish Borders ML12 6QH

Aberdeen